The Institute of Design and Production in Precision Engineering has a long experience in precision engineering.

The principal Areas of Work are:

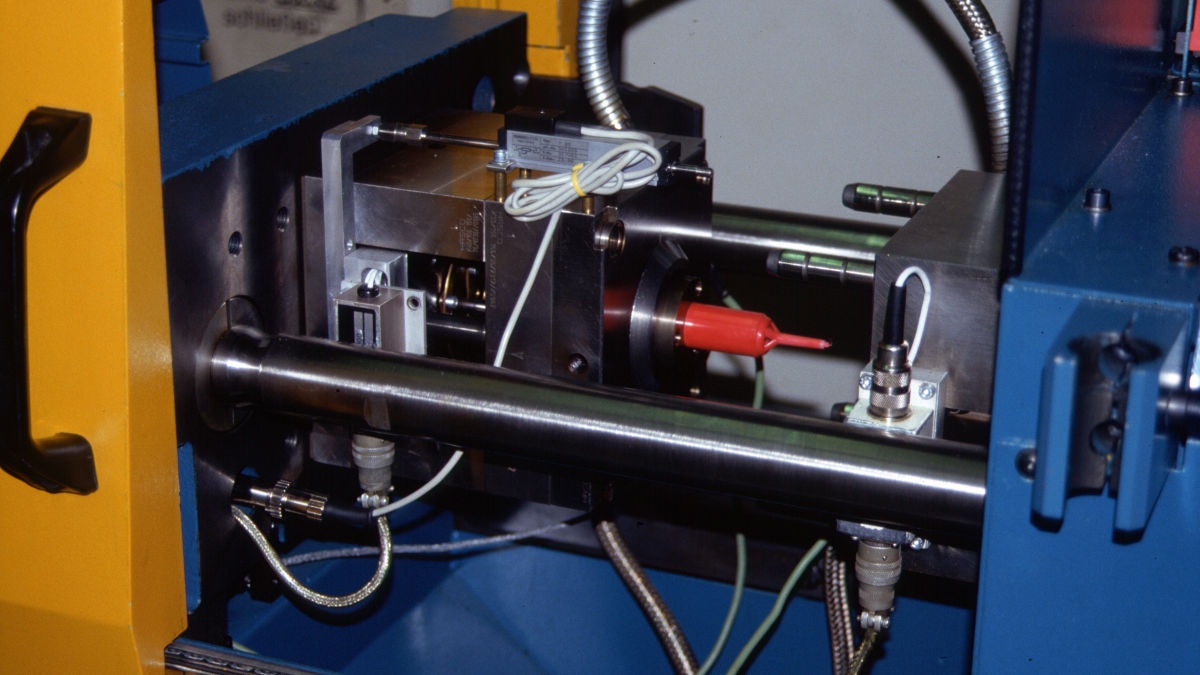

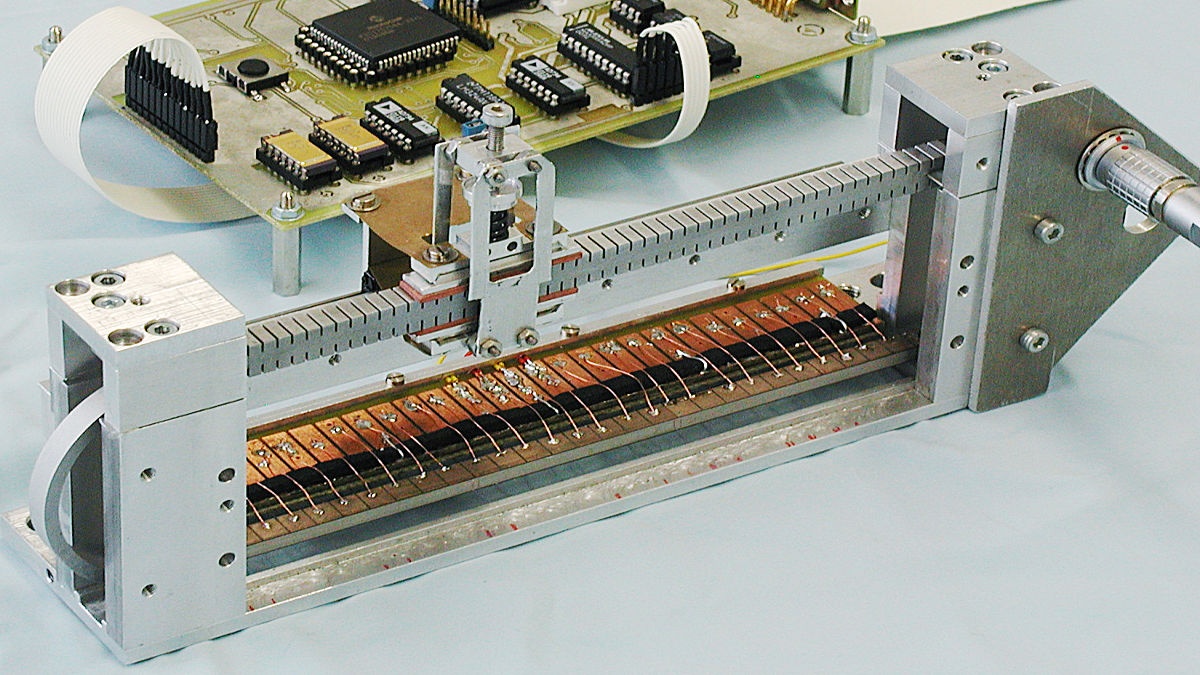

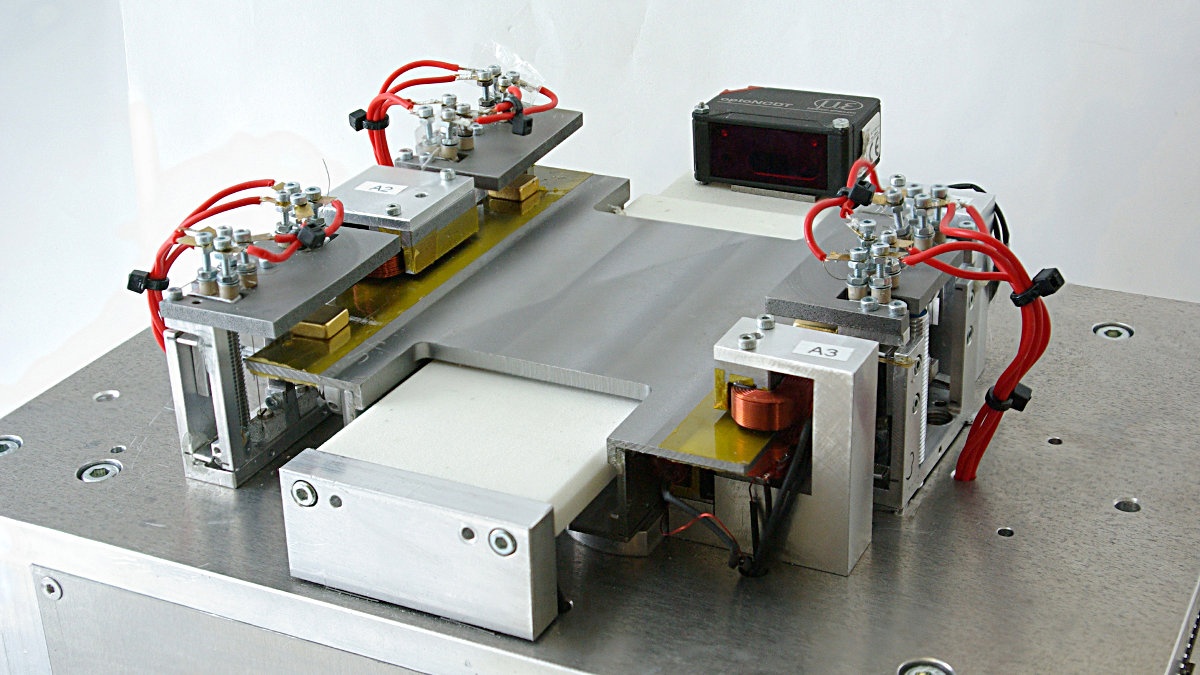

- Computer aided design of high energy magnetic circuits for permanent magnetically energized linear motor systems.

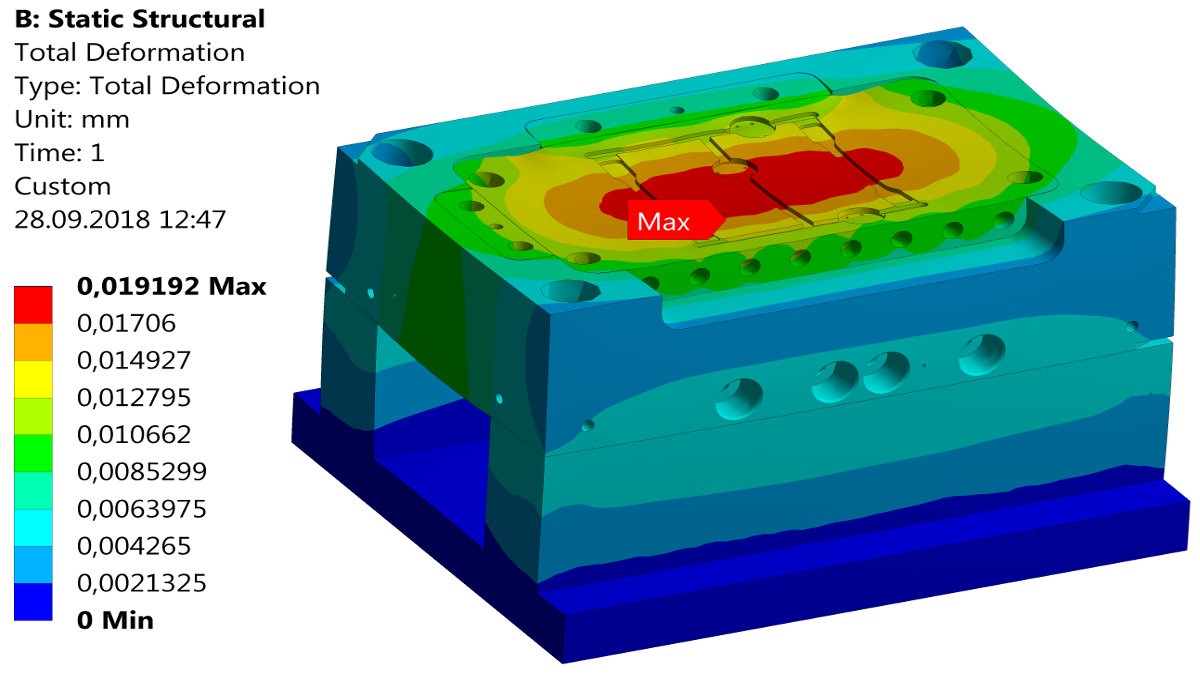

- Simulation and optimization of the magnetic circuits with FE-methods.

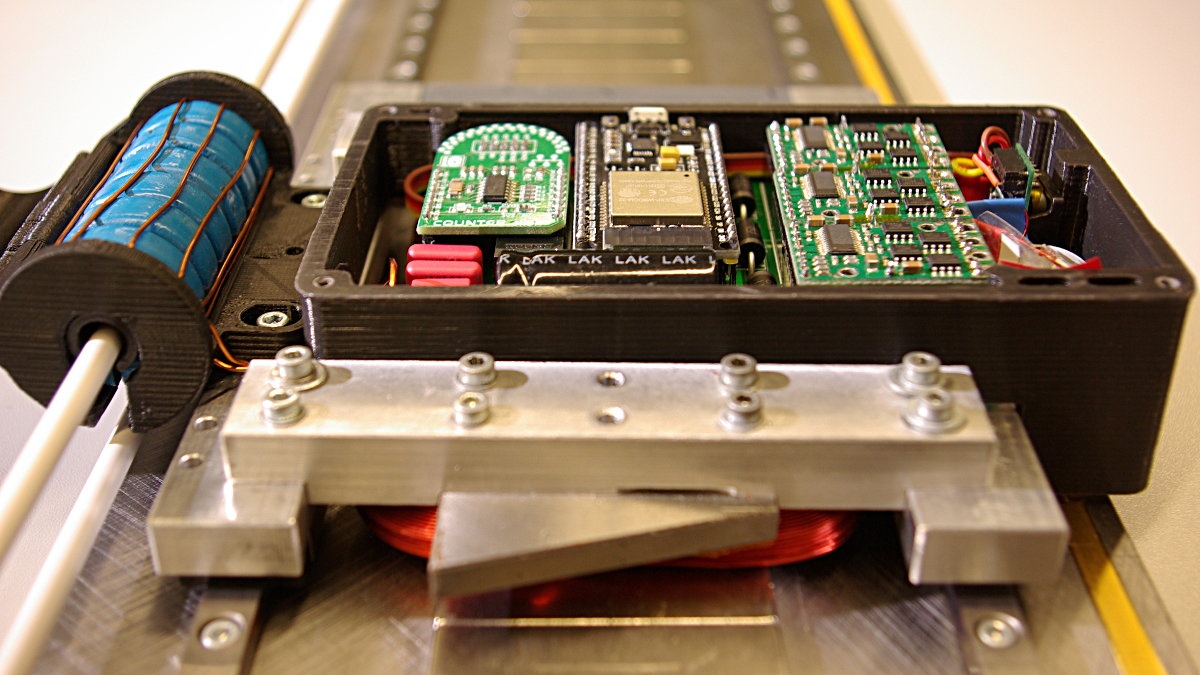

- Computer aided dimensioning, optimization and design of electromagnetical direct drive linear systems in precision engineering.

- Development and design of miniature direct drive systems with integrated measuring systems using the sensoric properties of the system.

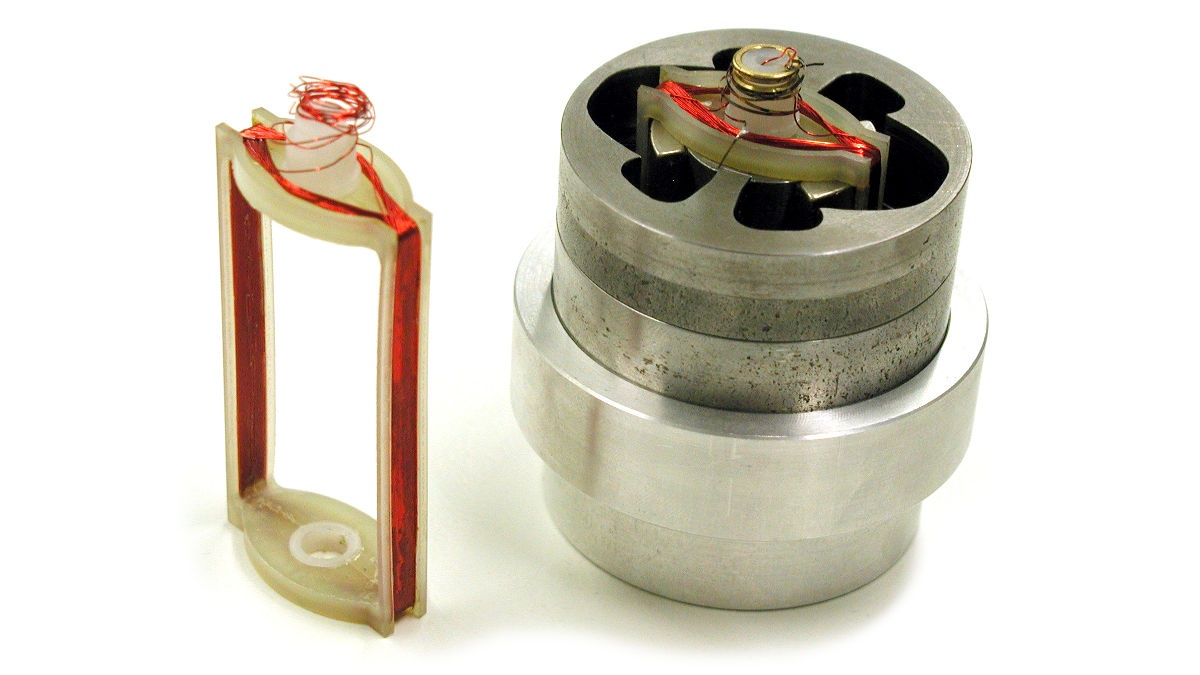

- Investigation and development of ultrasonic linear drives based on travelling waves.

- Simulation and optimization of the travelling wave using FE-methods.

- Production of precision parts and structures.

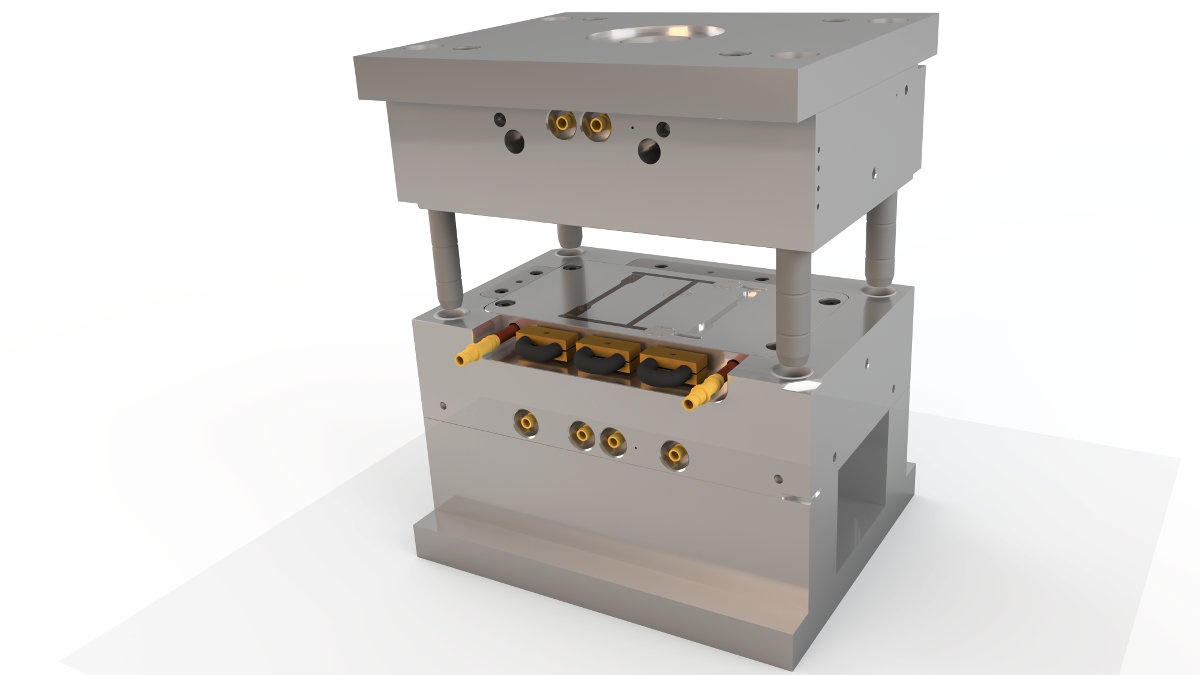

- Dynamic tempering of molds with induction heating.

- Production of polymer bonded magnets.

- Determination of forces appearing when opening the mold.

- Optimization of parts to save material by applying FE-methods.

- Tansfer and verification of new and already known reliability methods on precision drives.

- Experiments including endurance tests of precision drives.

- Development of new approaches to determine the system reliability in early design phases.

- Precalculating of the system reliability of mixed systems in early design phases.